Digital transformation

Digital transformation and sustainability for the industrial sector

Under pressure to improve profits and output while reducing emissions and meeting ESG requirements, industrial leaders are realising the enormous benefits that digitisation can bring.

For industrial assets, digital transformation is about leveraging industry 4.0 technologies at every level of the industrial process – from the actuators and sensors on the factory floor through to ERP solutions at the management and enterprise level.

This includes automation, machine learning, dynamic simulation, edge and cloud computing, allowing fast access to aggregated, contextualised and shared information across the organisation. Applying AI and ML using high performance computing, means data gaps, patterns and insights can be identified beyond the capabilities of traditional methods.

As a result, you are equipped to deliver finance-grade sustainability reporting, as well as other essential analysis for production reporting, mass and energy balances and process optimisation.

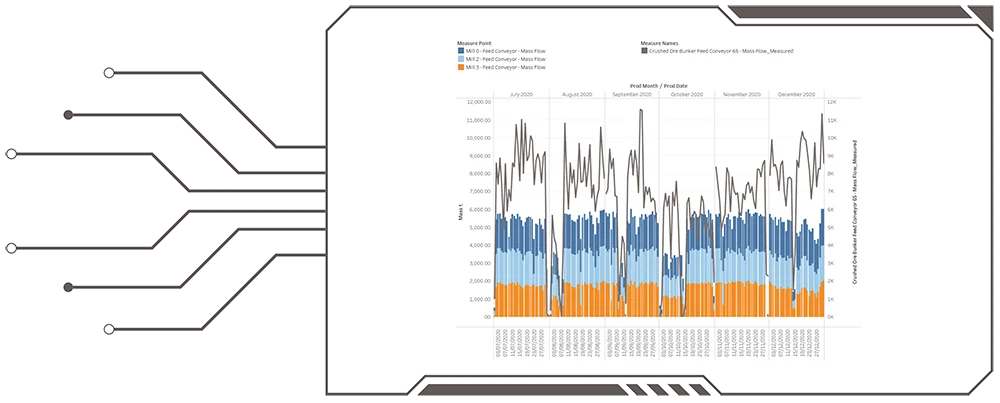

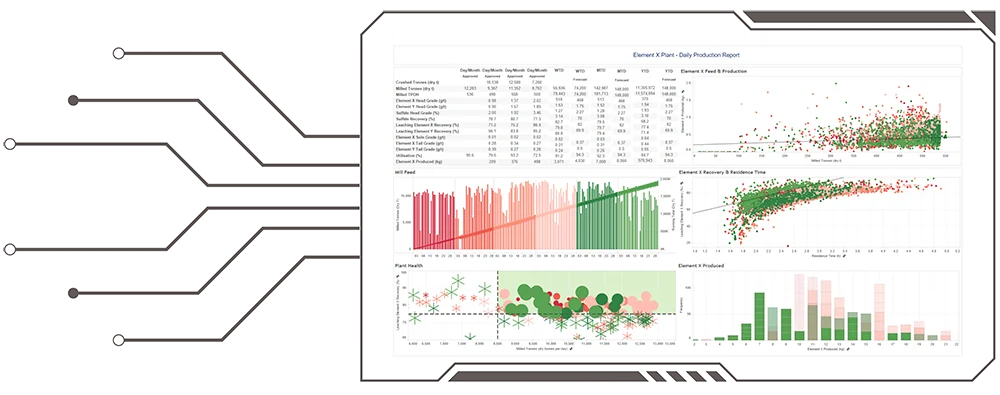

Production reporting across your operation

Accurate production reporting is used to quantify the performance of industrial assets, such as recovery and waste. It is also used to establish an accurate estimate of inventory. If there is a large discrepancy between actual and estimated inventory, there can be significant financial consequences. Poor estimation of recovery and losses can hide process issues and affect production planning.

Sustainability Tracker (ST) can produce detailed production reports for your industrial operation which enable you to:

- Monitor KPIs in one central dashboard

- Efficiently track and optimise product quality, costs and sustainability indicators

- Understand and improve overall product capacity

- Identify and address potential issues or negative trends before they become disruptive

- Capture data from connected devices at machine and instrument level, eliminating manual collection and human error

- Measure and optimise utilisation of equipment

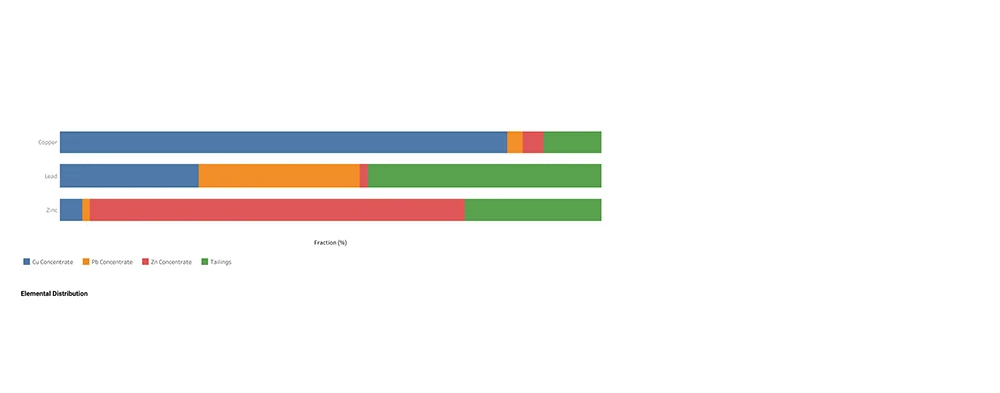

Mass and energy balance & materials/metal accounting

ST performs an asset-wide mass and energy balance using dynamic simulation connected to source data, which is used to perform a full reconciliation on the process and to calculate and report performance and production. This enables you to:

- Calculate every stream with a complete process flow diagram accurately representing flows within the asset. As operations are updated, so are the simulated model flowsheets for a complete process digital replica of the physical asset.

- Automate hourly mass and energy balance measurements by automatically importing, validating and contextualising the data from your instrumentation, laboratory and other sources.

- Assess the asset’s performance, identify instruments needing calibration, streamline sampling practices, and quantify previously unknown losses and emissions.

- Save time chasing up data from disparate sources to free up time to analyse the information and improve processes to maximise product yields and minimise costs.

- Track inventory via hourly calculations across every stream in your asset using real data as inputs – including elemental composition of streams and intermediate inventories.

Process optimisation

The ability to optimise your industrial asset using an industry-specific solution, is where your digital transformation project will quickly pay for itself, often before the software implementation has even been completed.

Aligning measured and calculated data will allow detection of instruments or sampling practices that may need to be assessed and resolved before they escalate.

ST can help optimise processes by performing an alignment analysis between the simulated calculated data from the dynamic model and the measured data from instruments and sensors.