Digital sustainability

Digitally measure key sustainability indicators

The World Economic Forum shows energy-intensive sectors already have the potential to reduce emissions by 4 to 10% in the short term by rapidly adopting digital technologies.

Achieving this will require a combination of partnership, digital talent and full transparency demonstrated by traceable, auditable and unalterable data and reporting.Accounting & reporting by scope – Climate & Nature related disclosures

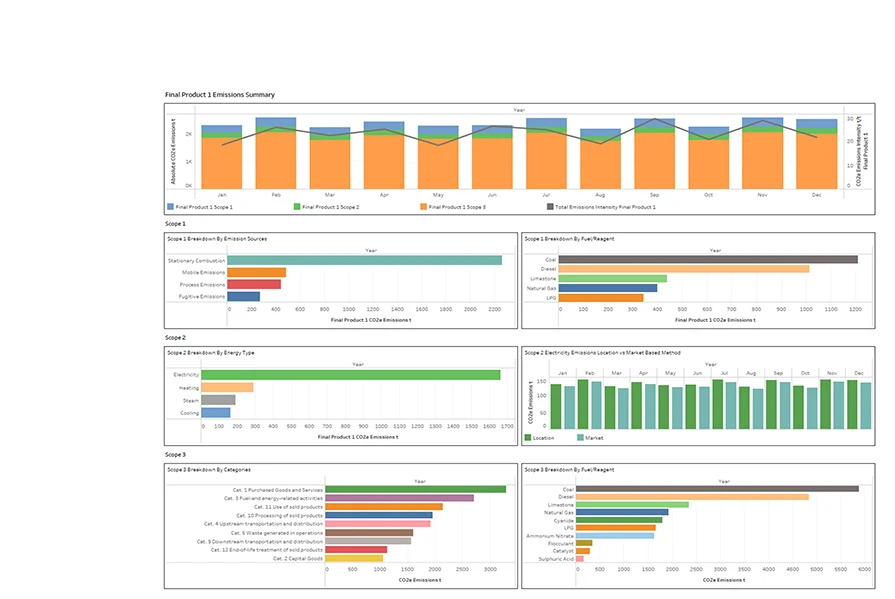

Scope 1

- Stationary combustion

- Mobile emissions

- Process emissions

- Fugitive emissions

Scope 2

Energy purchased

- Electricity

- Steam

- Heat

- Cooling

Emissions factors

- Location based method

- Regional or subnational emission factors

- National production emission factors

- Market-based method

Scope 3

Upstream

- Purchased goods and services

- Capital goods

- Fuel-and energy-related activities

- Upstream transportation and distribution

- Waste generated in operations

- Business travel

- Employee commuting

- Upstream leased assets

Downstream

- Downstream transportation and distribution

- Processing of sold products

- Use of sold products

- End-of-life treatment of sold products

- Downstream leased assets

- Franchises

- Investments

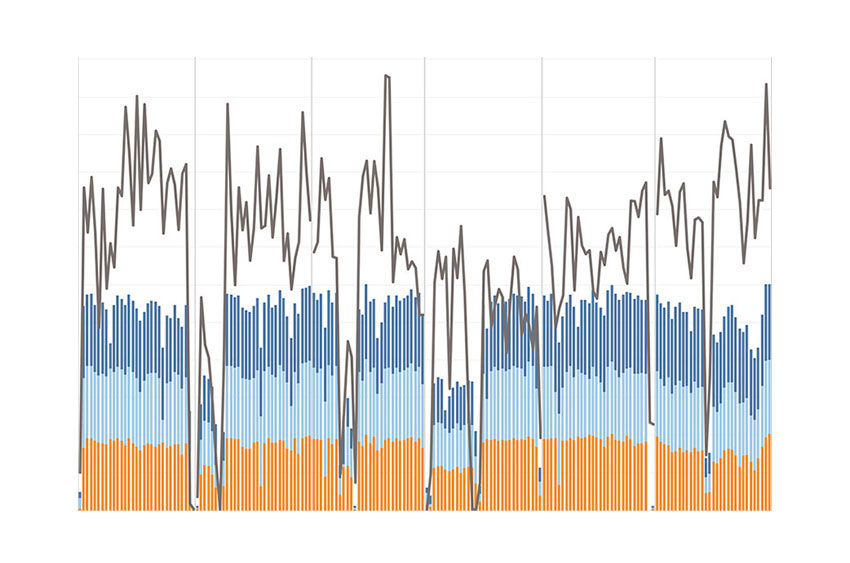

Start with accurate and granular activity data

At the heart of finance-grade sustainability reporting is accurate transparent and detailed activity data. Digital transformation for industrial organisations provides the tools to accurately collect and track this information.

While data is typically collected from onsite metering or purchase records, the gold standard is to create a digital twin of your operation and use source data to perform a granular asset-wide mass and energy balance, reconciled using dynamic simulation.

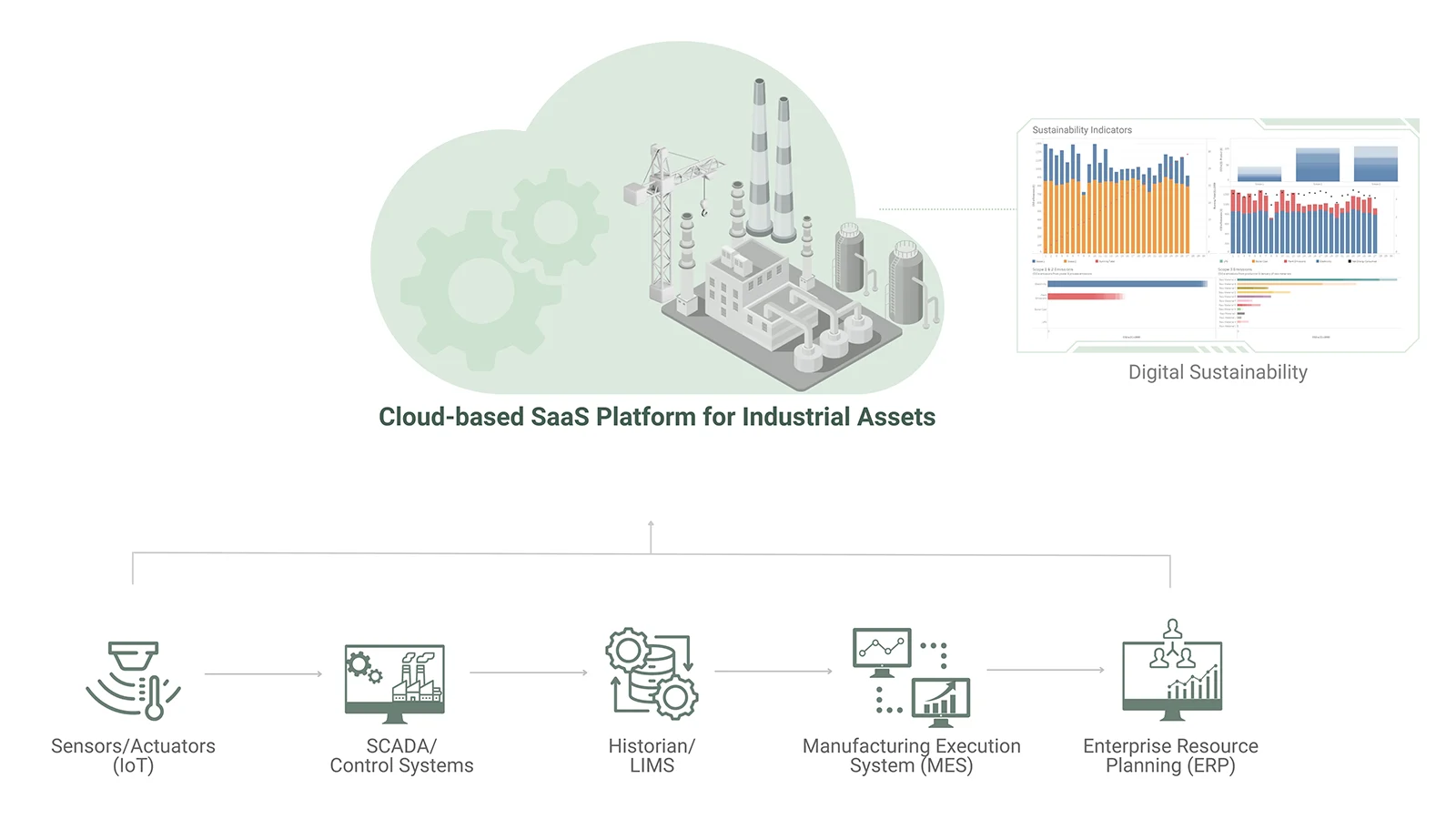

That’s where Sustainability Tracker (ST) comes in. Asset data is collected, validated, simulated and analysed across the site, to give rich insights across your operation, so you can report on a broad range of sustainability indicators.

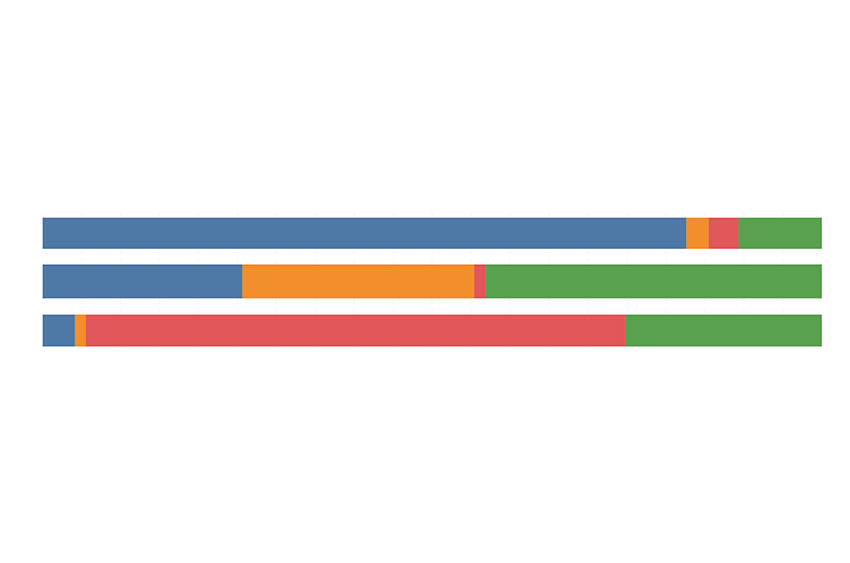

ST enables each validated data stream to be assigned a scope, boundary, category/source, and data type to derive the most accurate activity data throughout the industrial process.

Emissions factors are selected with access to internationally recognised third-party databases and the software maintains data tables for recognised emissions factors, supplier-specific and custom emissions factors.

It is essential to report emissions down to a product level

A combination of customer preferences, investor demands and tightening global regulations make it essential for industrial operations to track scope 1, 2 and 3 emissions right down to a product level. This is not only to help cut emissions across the product life cycle, but also to meet strict new reporting rules.

For example, the EU Carbon Border Adjustment Mechanism (CBAM) has legislated that embedded carbon emissions need to be reported down to a product level, as well as mandating digital tracking and access to this sustainability data. Major governing bodies across the globe are following suit.

Set targets, track & reduce emissions

Setting decarbonisation goals and tracking progress toward those goals requires two essential ingredients: finance-grade sustainability data and a robust, auditable GHG emissions accounting process. Sustainability Tracker (ST) helps you deliver on these ingredients and more.

Digital transformation for industrial operations

Accurate, granular and auditable sustainability reporting goes hand in hand with production accounting for your industrial asset. ST will not only provide finance-grade sustainability reports but also verified and contextualised production reporting, mass and energy balance and process optimisation.

Production reporting

One central dashboard to track, analyse, optimise and report on KPIs, quality, costs, capacity, sustainability indicators and more.

Material / mass and energy balance